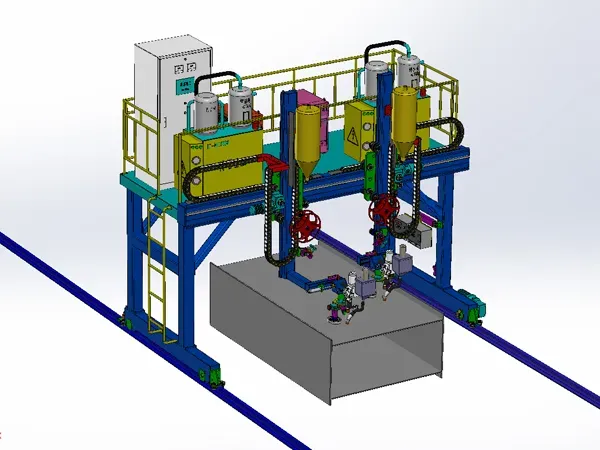

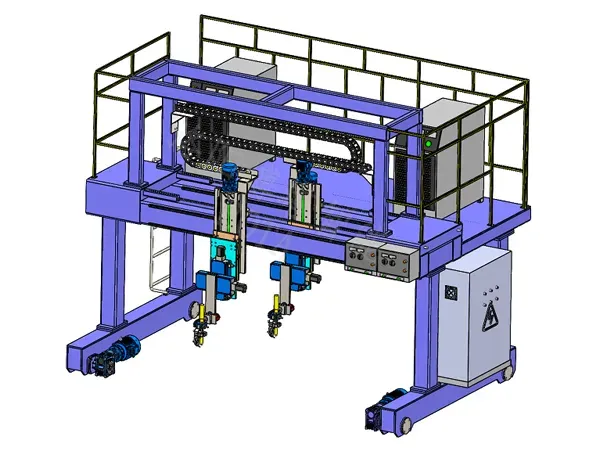

Gantry welding machine dominate the field of large-scale workpiece welding such as shipbuilding, engineering machinery, and bridge steel structures due to their high stability, wide coverage, and intelligent control system. This article deeply analyzes the advantages of gantry welding machines and provides professional reference for enterprise equipment selection.

Repeated positioning accuracy of ±0.05mm, ensuring that the straightness error of long welds (>10 meters) is ≤1mm/meter, supporting laser tracking or arc sensing real-time correction, and adapting to groove deviation. At the same time, the gantry welding machine can be equipped with 2-4 welding guns for synchronous welding, which increases efficiency by 300%. Each welding gun has independent parameter control (current 200-600A adjustable), which meets the requirements of multi-layer and multi-pass welding process.

The gantry welding machine can realize one-click programming: import CAD drawings to automatically generate welding paths, reduce manual teaching time, support offline programming, and increase equipment utilization by 40%. It also has an adaptive process library that can store more than 500 sets of welding parameters (such as MAG welding, submerged arc welding, narrow gap welding), and automatically match material thickness (6-150mm)

The welding material loss rate of the gantry welding machine is about 10% lower than that of the traditional manual welding machine, and the power consumption is only half of that. In the long run, the gantry welding machine not only has a long service life but also achieves the effect of reducing costs.

Fully enclosed protective cabin: equipped with radiation-proof glass and automatic rolling door. Isolate splashes and smoke, smoke purification system: integrated cartridge dust collector (purification efficiency ≥ 99%), in line with OSHA/GB16297 standards. Safety interlock device: emergency stop button, grating protection, overload protection and other multiple protection mechanisms

The gantry welding machine solves the problems of precision, efficiency and cost in welding large workpieces through rigid structure, intelligent control and high-efficiency design. With the integration of AI vision and digital twin technology, the gantry welding machine will evolve into a fully autonomous welding system with self-perception, self-decision-making and self-optimization in the future, and continue to empower high-end manufacturing!

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian