Improving the efficiency of a welding manipulator (often a robotic arm or a dedicated positioner used in automated or semi-automated welding) involves optimizing various aspects of the system and process.

Minimize Air Time: Reduce the time the manipulator spends moving between welds ("air cutting"). Optimize the path planning to take the shortest, fastest routes between weld points.

Optimize Motion Speeds: Use the highest safe and repeatable speeds for non-welding movements. Tune acceleration and deceleration parameters.

Weld Sequence Optimization: Plan the order of welds to minimize overall manipulator travel, reduce heat distortion (which can necessitate rework or slower welding later), and maintain optimal torch angles.

Offline Programming (OLP): Use OLP software to create, simulate, and optimize programs without stopping the production line. This maximizes manipulator uptime.

Use Appropriate Motion Types: Employ linear movements (L) for welding paths and joint movements (J) for faster transitions between distant points where path accuracy isn't critical.

Optimize Weld Parameters: Fine-tune voltage, wire feed speed (amperage), travel speed, and gas flow for maximum deposition rate and minimal spatter/defects, reducing post-weld cleaning and rework.

Select Efficient Welding Processes: Consider advanced processes like pulsed MIG/MAG, CMT (Cold Metal Transfer), or high-speed TIG variants if applicable, as they can offer higher speeds, lower heat input, or reduced spatter.

Improve Torch Angle and Stick-out: Ensure the torch angle and contact-tip-to-work distance (stick-out) are optimized and consistently maintained for stable arc and good penetration.

Design for Automation (DFA): If possible, influence part design to improve accessibility for the manipulator and simplify weld joints.

High-Quality, Repeatable Fixtures: Use fixtures that locate parts accurately and consistently every time. Poor fit-up is a major cause of inefficiency and weld defects.

Quick Changeovers: Design or utilize fixtures that allow for fast loading and unloading of parts. Consider indexing tables or dual fixture setups where one side can be loaded/unloaded while the other is being welded.

Optimize Fixture Access: Ensure the fixture provides clear access for the manipulator arm and welding torch without collisions.

Touch Sensing: Use the welding wire or a probe to accurately locate the start of weld joints, compensating for minor part variations.

Through-Arc Seam Tracking (TAST): For suitable joints, use TAST to allow the robot to follow the weld seam automatically, compensating for variations during welding.

Laser Seam Tracking/Vision Systems: Implement laser scanners or vision systems for more complex joint finding and real-time seam tracking, especially useful for parts with significant variability.

Adaptive Welding: Some systems can adjust welding parameters in real-time based on sensor feedback (e.g., joint gap variations) to maintain weld quality.

Preventive Maintenance (PM): Regularly maintain the manipulator (lubrication, checking belts/motors), welding equipment (liners, contact tips, drive rolls, gas nozzles), and fixtures. Unplanned downtime is a major source of inefficiency.

Tool Center Point (TCP) Calibration: Regularly check and calibrate the TCP. An inaccurate TCP leads to misplaced welds, requiring reprogramming or causing defects.

Robot Calibration: Periodically perform mastering or calibration of the robot itself to ensure positional accuracy.

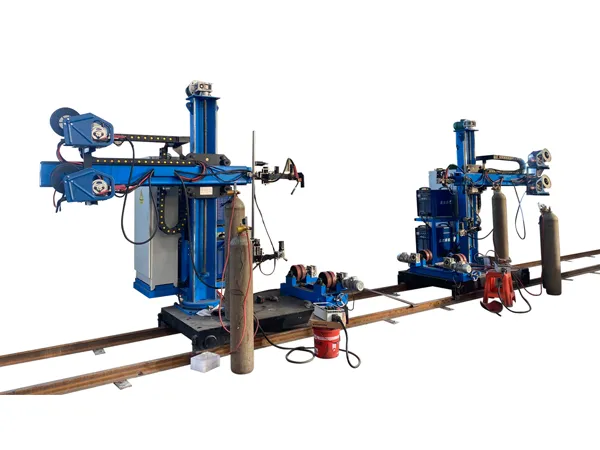

Appropriate Manipulator: Ensure the manipulator (robot arm, positioner) has sufficient reach, payload capacity, speed, and accuracy for the task.

External Axes/Positioners: Utilize servo-controlled positioners (turntables, headstock/tailstock) coordinated with the robot motion. This allows the part to be moved into optimal welding positions (e.g., flat position) which increases welding speed and quality, and improves torch access.

High-Quality Consumables: Use reliable welding wire, gas, and torch consumables to minimize feeding issues, spatter, and premature wear.

Skilled Programmers/Operators: Well-trained personnel can create more efficient programs, troubleshoot issues faster, and perform setups correctly.

Streamlined Workflow: Optimize the overall cell layout and material flow to and from the welding station. Minimize operator waiting time.

Track Key Metrics: Monitor cycle times, uptime, downtime reasons, first-pass yield (quality), and consumable usage.

Analyze Data: Use the collected data to identify bottlenecks, recurring problems, and areas for improvement.

By systematically addressing these areas, you can significantly improve the overall efficiency, throughput, and quality of your welding manipulator system. It often requires a holistic approach rather than focusing on just one aspect.

What are the maintenance tips for welding positioner

No information

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian