Welding positioner mainly refers to a type of equipment that can play an auxiliary role during welding. It is mainly used for welding that requires the workpiece to be able to achieve position shifting during welding, so that a relatively ideal welding position and an ideal welding rate can be achieved. Welding positioner can be used with many other types of machines to form an automatic welding type, and can also be used for workpiece position shifting during manual welding. There are many types of positioners on the market, so it is also a problem for consumers when choosing. Here are some precautions for purchasing welding positioners for your reference.

1. Double-column single-rotation type: The main feature of this type of welding positioner is that the motor-driven working device at one end of the column runs in one rotation direction, and the other end is driven by the active end. The columns on both sides can be designed as lifting type to meet the welding needs of product structures of different specifications. The disadvantage of this type of welding positioner is that it can only rotate in one circumferential direction. Therefore, when choosing, pay attention to whether the weld form is suitable.

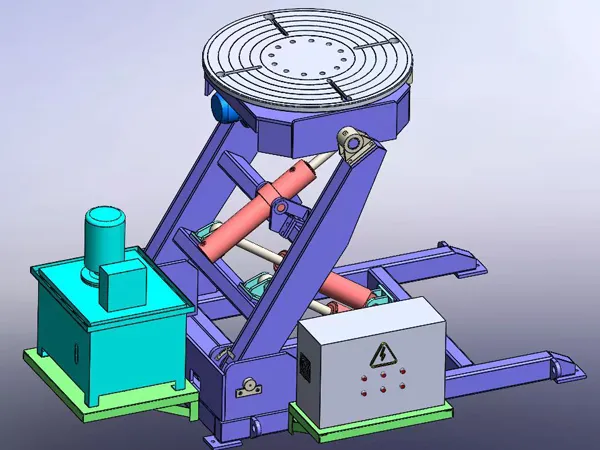

2. Double-seat head-tail double-rotation type: The double-seat head-tail double-rotation type welding positioner is the activity space of the welded structural parts, and adds a rotational freedom on the basis of the double-column single-rotation welding positioner. This type of welding positioner is more advanced, with a large welding space, and can rotate the workpiece to the required position. It has been successfully applied in many engineering machinery manufacturers.

3. L-shaped double-rotation type: The working device of this type of welding positioner is L-shaped, with rotational freedom in two directions, and both directions can rotate ±360° arbitrarily. The advantages of this welding positioner are good openness and easy operation.

4. C-shaped double-rotation type: The C-shaped double-rotation welding positioner is the same as the L-shaped double-rotation welding positioner, but the tooling fixture of the welding positioner is slightly changed according to the shape of the structural parts. This type of welding positioner is suitable for welding structural parts such as buckets of loaders and excavators.

1. When choosing, you should first look at the function of the machine. Check whether the specified translation or vertical movement is a curve or a straight line.

2. Check whether the movement during rotation is continuous or intermittent. Generally, choose a machine that can perform linear motion and achieve continuous flipping.

3. Check the overall speed of the machine during movement, whether it is fast or slow, whether it is a constant speed movement or a variable speed movement. These need to be clarified when purchasing.

4. Check whether the machine is stable and accurate when completing these movements.

5. Check the function of some parts. The positioner must have the function of self-locking to ensure safety when turning or achieving some relatively large tilting effects.

6. The weight of the welding positioner and the distance between the center of gravity and the eccentricity of the weldment on the entire work surface should be guaranteed to be within the corresponding data range, and it must also be guaranteed to have a certain capacity.

7. If you choose a welding positioner for circumferential welding, you should consider the rotation speed according to the groove of the weldment. The speed should be guaranteed to be within the range of the positioner speed adjustment, and there is also a requirement for the stability of the working platform in operation, whether it can meet the processing of the entire process.

8. If the size of the weldment on the outer contour is relatively large, it is necessary to consider the inclination of the welding positioner workbench, or whether the inclination angle can meet the welding position of the weldment, etc. When the inclination angle contacts the weldment, then when selecting it, it is necessary to have a larger gap from the ground, so as to ensure the processing requirements of the entire welding.

In our company, the welding positioner has quietly become an indispensable equipment in the manufacturing industry, and it is classified as a welding auxiliary machine in the welding field. In recent years, this product has made great progress in our engineering machinery industry and has been widely used. In terms of type series and variety specifications, there are about ten series and more than one hundred varieties and specifications. It can be said that welding positioner is a product with many varieties, high technical level, and small, medium and large development.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian