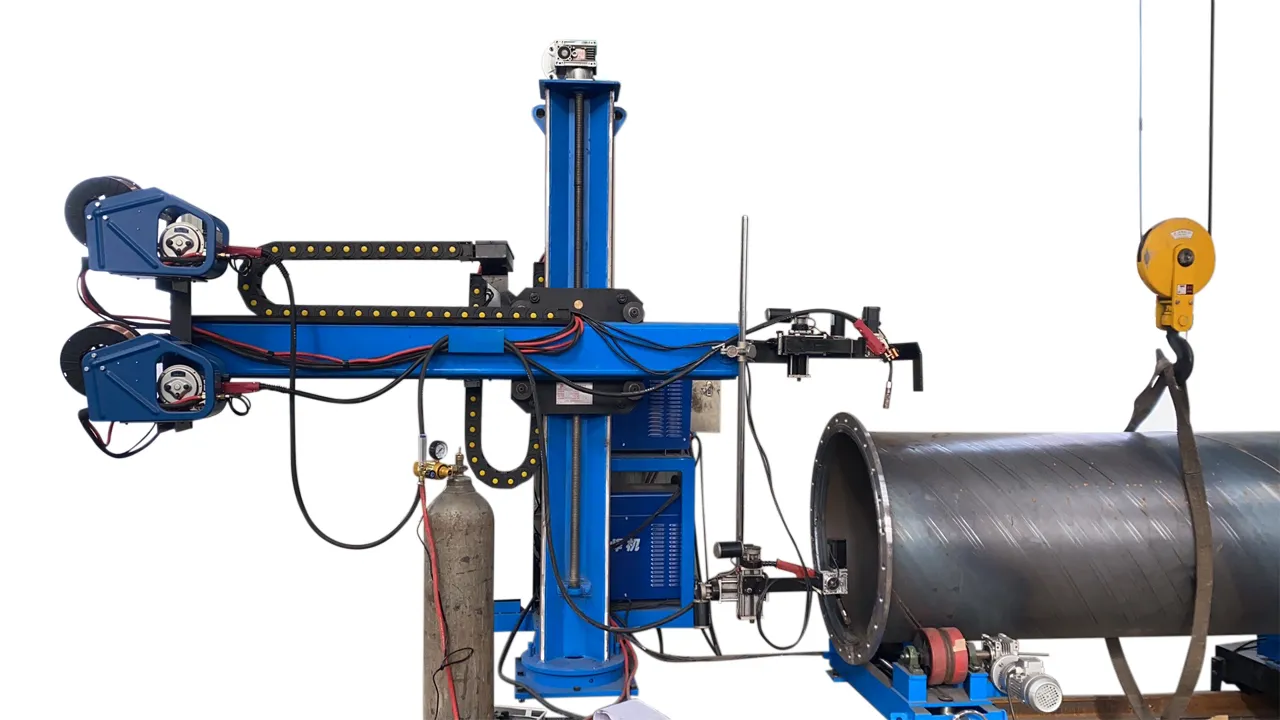

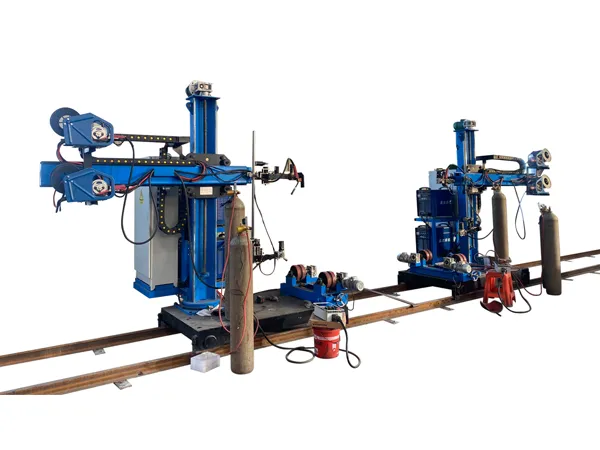

Welding column boom is an important equipment used for welding work. To ensure its normal operation and safe use, it is important to perform regular maintenance.

1. Electrical system maintenance

Check whether the electrical components such as the power line, switch, button and controller of the welding column boom are intact, and perform necessary maintenance and replacement. Check whether the joints of the welding cable and connector are loose or damaged, and perform necessary cleaning and tightening. Check whether the power supply and grounding of the welding machine are normal to ensure the safety and reliability of the electrical system.

2. Mechanical structure maintenance

Check whether the frame, support and connecting parts of the welding column boom are firm. If they are loose or worn, they should be repaired or replaced in time. Check the transmission system of the welding operation machine, including transmission belts, chains, gears, etc., to ensure its normal operation and transmission efficiency.

Check the guide system of the welding column boom, including guide rails, guide columns, etc., to ensure the stability and accuracy of the welding head.

3. Lubrication system inspection

Check the lubrication system of the welding column boom, including the oil pump, oil pipe, oil nozzle, etc., to ensure the smooth supply and circulation of the lubricating oil. Replace the lubricating oil, and clean or replace the oil filter to ensure the normal operation of the lubrication system. According to the use of the welding operator, determine the lubrication cycle and lubrication parts, and perform lubrication maintenance regularly.

4. Welding power supply inspection

Check the welding power supply part of the welding column boom, including the transformer, rectifier, capacitor, etc., to ensure its normal operation and safety. Check the cooling system of the welding power supply, including the fan, heat sink, etc., to ensure that the heat dissipation effect of the welding power supply is good.

Clean the inside and outside of the welding power supply to ensure good heat dissipation and prevent dust and dirt from affecting the welding power supply.

5. Safety device inspection

Check the safety devices of the welding column boom, such as the emergency stop button, leakage protector, etc., to ensure their normal operation and safety.

Test the leakage current and insulation resistance of the welding column boom to ensure the safe use of the welding column boom.

1. Safe operation

When carrying out overhaul, be sure to follow the safe operating procedures and never ignore safety issues. If necessary, disconnect the power supply and put up warning signs to prevent accidental start-up and injury.

2. System test

After the overhaul is completed, perform a system test to verify the function and performance of the welding column boom. This includes checking the working status of the electrical system, mechanical structure, lubrication system, and welding power supply to ensure their normal operation.

3. Records and reports

Record the maintenance and repair work during the overhaul in detail and prepare an overhaul report. The record should include the date of the overhaul, maintenance items, replaced parts, test results, etc. for subsequent reference and tracking.

Regular inspection and maintenance of welding column boom can ensure its long-term stable operation and extend its service life. At the same time, it can also improve welding quality and operational safety, providing reliable support and guarantee for welding work.

No. 1 Intersection of Chuangye Avenue and Weilai Avenue,

Yiyang County,Luoyang City, Henan Province, China

+86 400-0379-069

Copyright © 2023 An Automated Welding and Cutting Equipment Manufacturer Focusing on Welding Column Boom and Welding Rotator | All Rights Reserved Technical support: ShangXian